Customer-Centered Construction

Source Environmental Corrosion Corp.

Your Source Corrosion cathodic protection system is designed by a NACE accredited Cathodic Protection Specialist to provide maximum long-term protection customized to your specific needs – lifespan, protection level, facility expansion, installation timing and budget.

Not only do we perform our work to the highest standards of quality, but we take the time to understand your facilities and make recommendations that provide the most options for you to manage your business in the years to come.

Here are some examples of our work:

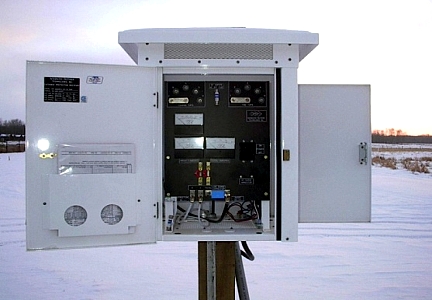

Rectifier

Pictured is a rectifier installed near Stettler, AB. This particular model by Integrated Rectifier Technologies of Edmonton, Alberta.

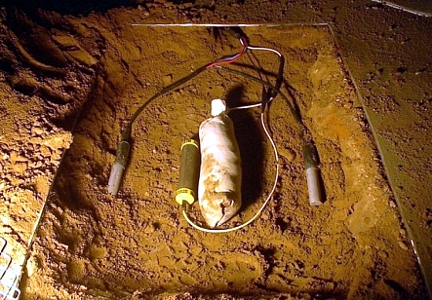

Horizontal Anode Bed with Canister Anodes

Installed in a muskeg region in the Slave Lake AB area. Our vertical applications include semi-deep and deep well configurations. Source Corrosion will also design and install a variety of other systems that focus on protection of tank bottoms, under ground storage tanks, oil & gas gathering, transmission and distribution pipeline systems through the use of high silicon cast iron, mixed metal oxide, sacrificial magnesium and zinc anodes.

Reference Electrode System

Reference electrode system for monitoring cathodic protection levels under a tank. From left to right: coupon reference, Copper-Copper Sulphate permanent reference electrode, zinc reference electrode and coupon reference.

Negative current drain points

Negative Electrical Continuity Bonding via Stainless Steel Banding

Our Experience Pays When Designing Your Cathodic Protection System

If you focus on the exposed flange in the photo there is an electrical insulation kit. Also in this photo, there are insulation kits under the galvanized metal cladding. From our experience, we know that this type of cladding used in this manner can give the cathodic protection current a route to actually bypass the insulation kit, thereby nullifying the intended effect. This type of current transfer can also be enabled by the installation of heat trace wires which are shown in this photo (black cables).

Our Experience Pays When Designing Your Cathodic Protection System

This is a semi-deep installation where the anode bed test station has been installed directly over top of the anode excavation bore. This is problematic as it allows gas created by the anode bed to vent directly through the test post causing the anode connection terminals to corrode. Not only does this dramatically change the operational status of the cathodic protection system but it causes current discharge overload on the anodes that remain functional. These remaining anodes will fail prematurely resulting in the life expectancy of the system to drop dramatically. This could have been avoided by simply offsetting the placement of the test station, incorporating larger vent tubing or by sealing off the poly post portion of the test station.